Petersen Aluminum

Petersen Aluminum Corporation was founded in 1965 as a metals service center to the architectural metal industry. At Petersen we strive to provide products of the highest possible quality within reliable, dependable lead-times. Our strong national sales base allows PAC to maintain large inventories and cost economies to our customers. In addition to our Chicago-based headquarters, we maintain full production facilities in Annapolis Junction, Maryland; Tyler, Texas; Acworth, Georgia and Fridley, Minnesota.. Our complete catalog is on this website and is available in standard 3-ring binder as well as CD-ROM format. Technical assistance and service are provided by our staff and complimented locally by our nationwide organization of architectural representatives. We are prepared to offer assistance in material selection, finish specification, and budgeting. As the scope of our applications is so wide, we encourage your inquiries.

Architectural Sheet and Coil

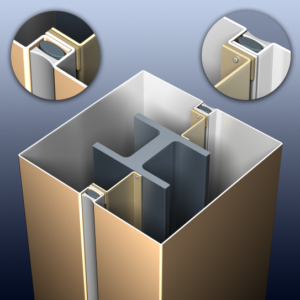

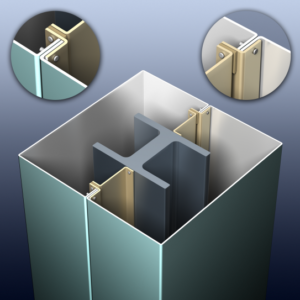

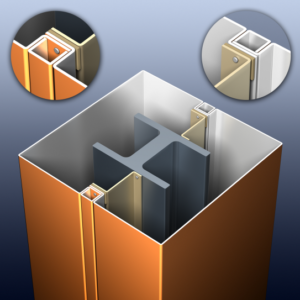

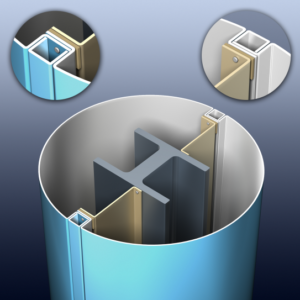

Square Column Covers

The Endurex line of exterior architectural products focuses on extending the life of the building. The Endurex 300 is the most innovative “next generation” glazing and storefront panel available.

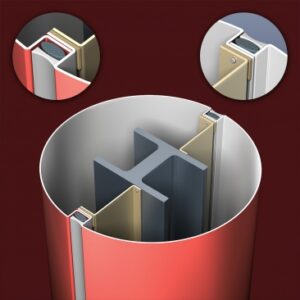

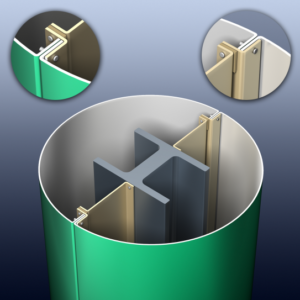

Round Column Covers

PAC-CLAD’s line of round and square metal column covers offers architects superior design flexibility for structural beam applications, both interior and exterior. Utilizing a wide range of materials, including aluminum in an unmatched range of standard and custom colors, anodized aluminum, aluminum composite, stainless steel and copper, Petersen can custom fabricate to meet the most demanding specifications for metal column casing and covers.

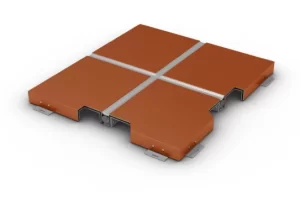

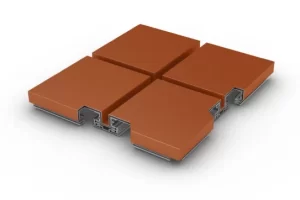

Composite Wall Panels

PAC-CLAD offers another dimension in design flexibility with its series of Composite Wall panels. PAC’s panel systems provide unmatched performance and stunning visual effects for any commercial or retail application.

The PAC-3000 CS panels are comprised of an .020 face and back skin thermobonded to a polyethylene or fire-retardant core. Panels are formed by a rout and return process utilizing computer controlled routing equipment. This state-of-art fabrication insures tight tolerances and accurate panel dimensions. Staggered angle clips mounted to the panel allow for each panel to be installed and adjusted individually.

The PAC-3000 RS is a rain-screen system that eliminates the use of caulk, utilizing clean reveals for an architecturally pleasing system. The system is constructed with aluminum composite material (ACM), available in a wide range of finishes and colors to complement any design scheme. Extrusions are fixed to the perimeter of the panel and nest into the extruded track which is attached to the substrate. The result is a free-floating panel installation since the panel is not fastened to the substrate.

The PAC-3000 AP panels provide a nearly endless selection of materials, finishes and configurations. Panels can be fabricated out of painted or anodized aluminum as well as stainless steel. Panel configurations can be customized to suit your application.

Chicago Corporate Headquarters

1005 Tonne Road

Elk Grove Village, IL

P: 800-PAC-CLAD

F: 800-722-7150

www.pacclad.com

Annapolis, Maryland

9060 Junction Drive

Annapolis Junction, MD 20701

P: 800-344-1400

F: 301-953-7627